Is it possible to use motors in series? This is one of the most frequently asked questions we receive from our customers. It is, in fact, an interesting application, used in different contexts and industries. Think, for example, of machines equipped with fans to distribute fertilizer or blades that cut vines: they rely precisely on the combined action of several motors.

So the answer is yes. It is possible to use Vivoil hydraulic motors in series, provided that the version with external drainage properly connected to a zero-pressure zone is being used and the two basic parameters that supply energy to the system are taken into account: inlet pressure and inlet flow rate.

How motors work in series

The hydraulic motors are connected to each other and work in sequence: the first motor receives oil from the supply-which makes it move-and the oil leaving the first one feeds the second motor, which moves and passes the supply to the next one, and so on. In this process, power is divided among the different motors. As a result, their power is gradually reduced: to half if there are two motors in series, to 33% if there are three, etc.

Power is distributed according to the number of motors used, which results in the output pressure in all motors except the last one being greater than zero. This condition can lead to the shaft seal failure and subsequent oil leakage. To prevent this, a protection is needed on the oil seal.

Provide drainage to reduce pressure on the oil seal

In almost all types of Vivoil hydraulic motors, the capacity of the oil seal to withstand stress is 6 bar, because they are equipped with a reinforced shaftseal with a supporting washer. But if the motors work in series, the output pressure is normally higher, because the pressure exerted on the shaft seal is the same as the motor output.

If you decide to opt for motors in series, it is therefore essential to use motors with external drainage to be connected to a zero pressure zone. In fact, the drainage is connected directly to the back of the shaftseal and prevents it from being stressed by the output pressure.

Additional tips for those who use motors in series

In addition to drainage, when using motors in series, we recommend that you consider some optional extras.

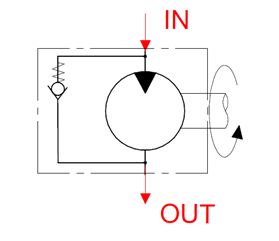

1 – Anti-cavitation valve, useful in case of motor blockage

The anti-cavitation valve, in the case of instantaneous blocking of rotation, prevents abrupt stresses, which can damage the machinery.

This is the situation that occurs, for example, in some cutting machines used in forestry. When the blade, designed to cut off stumps, hits a log and stops suddenly.

If the blockage is present in the second motor, the oil leaving the first motor can no longer pass to the second motor.

In this situation, the system relief valve limits the pressure on the first motor.

On the second is added the inertial effect of the first, which, as it continues to turn, works as a pump and further raises the pressure on the second motor.

To avoid the inertial effect, one can proceed by applying an anti-cavitation valve to the first motor, which allows internal oil recirculation.

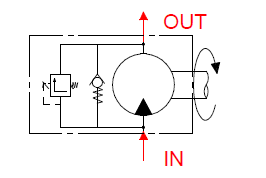

2 – Pressure relief valve, to protect the motor from pressure spikes

Another option we recommend you consider is the relief valve applied to the engine. It serves to protect it more readily in the event of a surge.

The valve sends the oil directly to the drain, bypassing the motor.

3 – Combine the action of anti-cavitation valve and relief valve

Another possibility is to combine the action of the two valves to reduce both risks simultaneously.

Which optional extras to choose?

In addition to those mentioned so far, other special solutions are possible, which you can find in our article on optional extras and special solutions to be applied to motors.

Do you need help? Contact us, we can recommend the most suitable optionals for your project.