We have devised a number of special solutions to make our hydraulic motors even more powerful and resistant: 11 optional extras that you can integrate into the Unidirectional Hydraulic Motors and Reversible Hydraulic Motors of the Vivoil range.

Let’s see what they are, what they are used for and some examples of applications.

1 – The bearing support

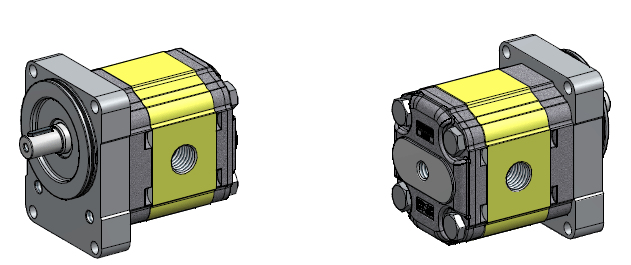

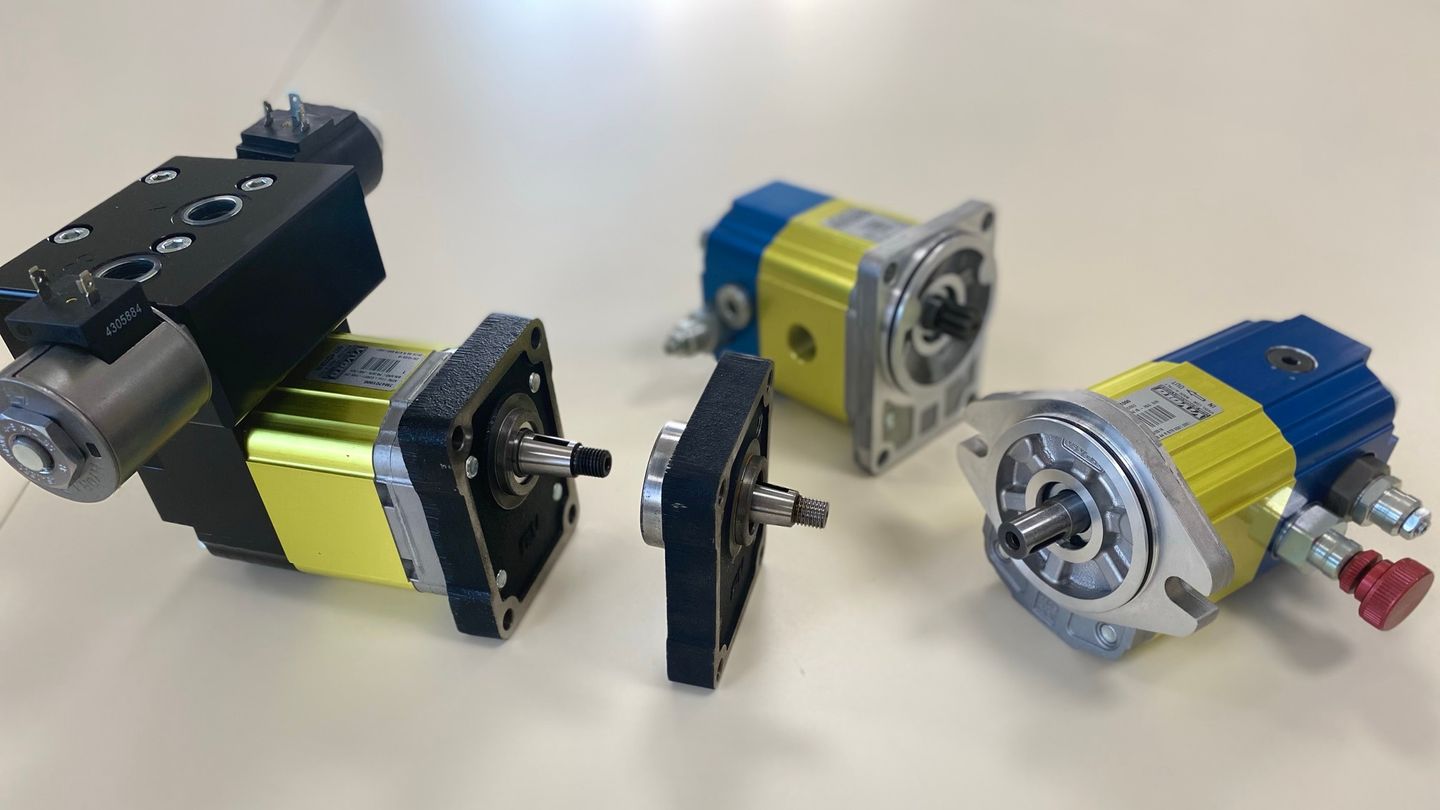

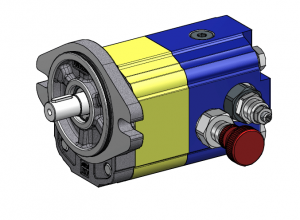

The bearing support is an option for our hydraulic motors that increases resistance to radial and axial loads. It is useful in various sectors and applications, in the case of transmissions with pulleys, toothed wheels and fans and in general when objects with a high mass have to be rotated. In the following picture you can see the bearing support fixed to the hydraulic motor and in an exploded view.

Different types of output shaft and flange are available:

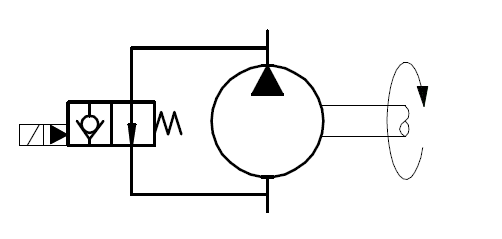

2 – Anti-cavitation valve

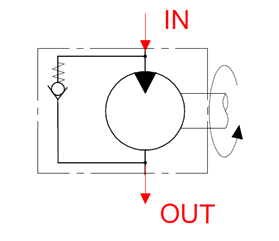

The anti-cavitation valve is an optional extra that is used to minimise the risk of damage to the motor due to cavitation: it is useful in the event of the oil supply to the motor being cut off to prevent the motor from stalling by allowing free rotation. The most common use is in the presence of high rotating masses and/or systems with closed-centre distributors. It is useful, for example, for motors that make up cooling fans and lawnmowers.

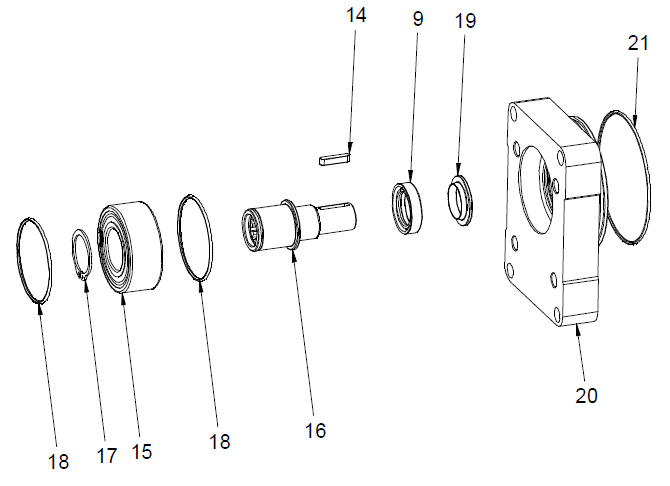

In the following image you can see the relevant hydraulic diagram:

3 – Pressure relief valve

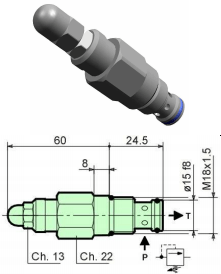

The pressure relief valve is used to limit the pressure on the hydraulic motor and thus protect the motor and other components from damage caused by pressure peaks. It controls the oil pressure, limiting it to the valve’s set value.

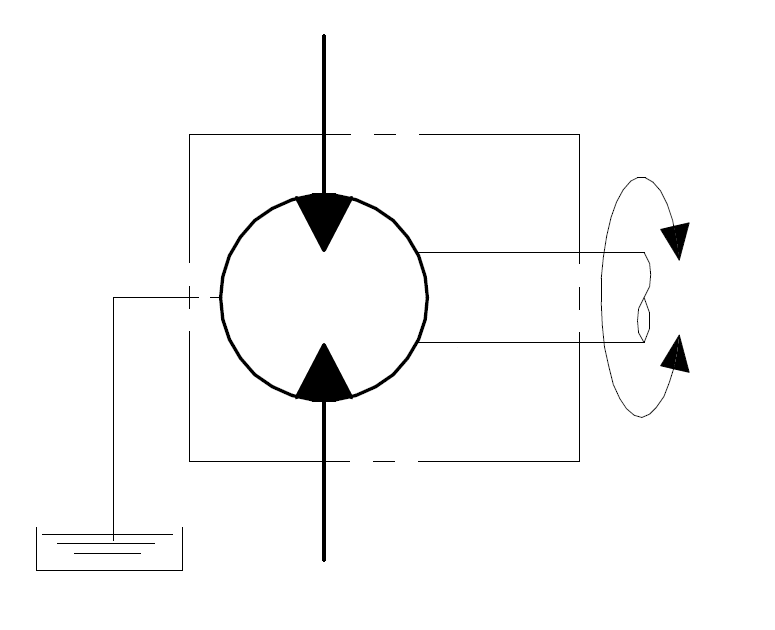

In the following picture you can see an example of a pressure relief valve:

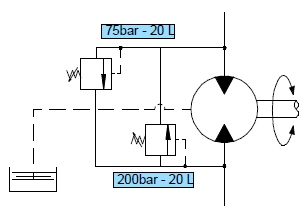

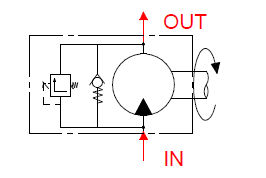

4 – Anti-cavitation valve + pressure relief valve

The anti-cavitation + pressure relief valve combines both functions of the two valves and therefore avoids, at the same time, both the risks associated with excessive pressure and those from cavitation. This optional extra is also normally used in motors that make up cooling fans and lawnmowers.

In the following image you can see the relevant hydraulic scheme:

5 – Speed regulator

The speed regulator allows the user to have direct control of the speed of rotation of the motor shaft. It is useful in several cases, particularly when the speed must be constant, regardless of the flow rate. Its applications range, for example, from cooling fans to machines in the agricultural sector.

In the image below you can see the speed regulator applied to a hydraulic motor:

6 – External drainage for unidirectional motors

External drainage is an option for unidirectional hydraulic motors and serves to preserve the internal seals of the motor from high pressures. It is normally used in series motors or motors with a pressure relief.

In the following image you can see how it works:

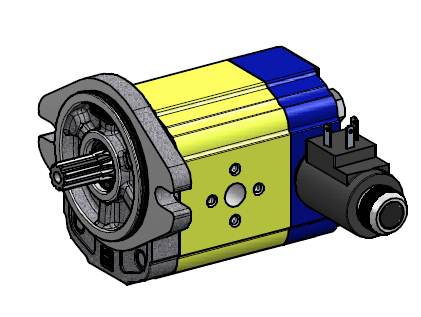

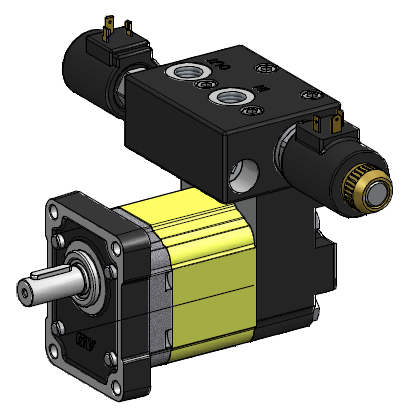

7 – Fan drive

This is a system comprising a motor with a proportional relief valve, a distributor to reverse the direction of rotation and an anti-cavitation valve. The fan drive variant of Vivoil hydraulic motors is used to connect the motor directly to a cooling fan, to control its speed and direction of rotation with the help of an electronic management system connected to sensors and/or the motor.

It is used, for example, in the fans of agricultural and industrial machinery.

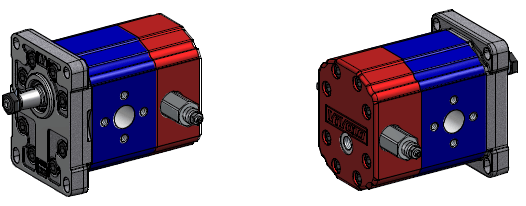

8 – Double cross relief valve

The double cross relief valve on reversible motors is used to regulate the pressure in the two directions of rotation.

In the images below you can see the double valve and its hydraulic diagram:

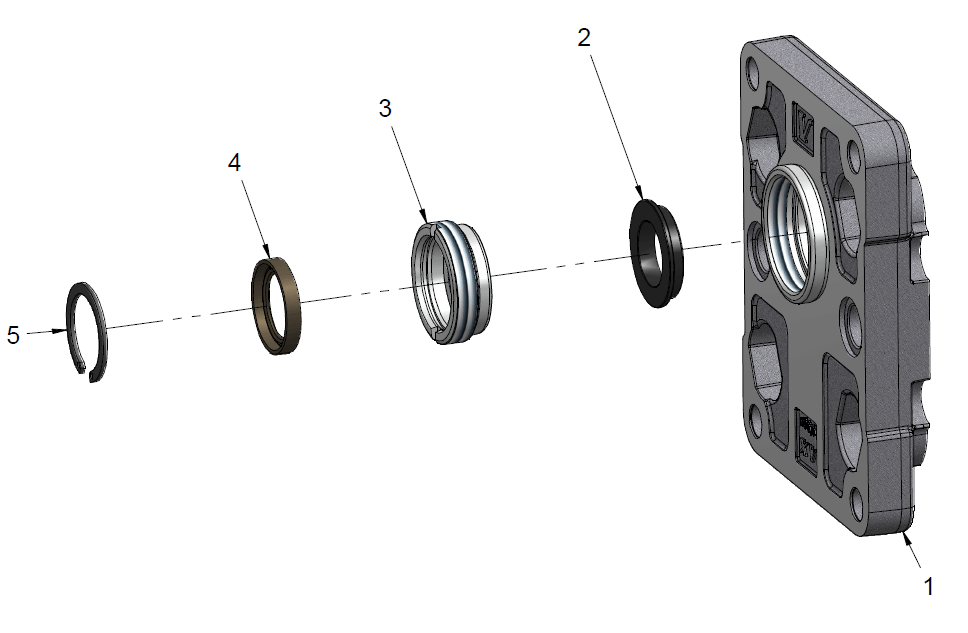

9 – High-pressure oil seal

As a standard in Vivoil engines, we use an oil seal with a supporting washer, which guarantees good pressure sealing up to 6 bar continuous. The high-pressure oil seal, on the other hand, guarantees sealing up to 25 bar continuous at 1500 rpm.

In fact, we recommend integrating it in unidirectional motors with drainage pressures up to 25 bar and in reversible motors for drainage pressures up to 25 bar.

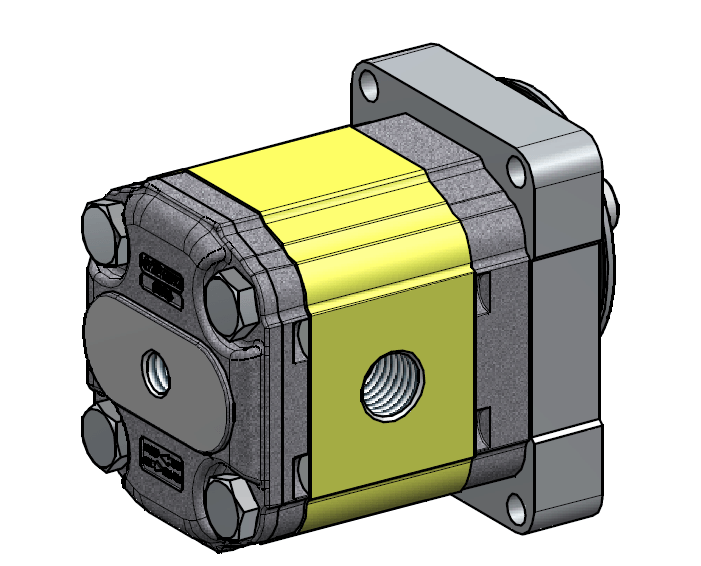

In the following image you can see the high-pressure oil seal in an exploded view:

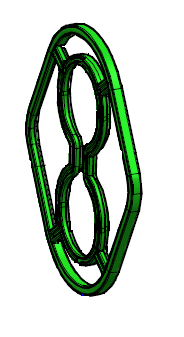

10 – VITON® gaskets

VITON® gaskets are elastomers which, when applied on the motor, make it more resistant to oils at higher temperatures.

In this image you can see the detail of the gasket:

11 – Electric bypass valve

The electric bypass valve is used to divert the flow of oil from the inlet directly to the engine exhaust. The valve is activated by an external electrical signal. It is normally used in air compressors and water pumps.

In the drawing below you can see the valve applied to the motor and the hydraulic diagram:

Do you want to know which of our special solutions for hydraulic motors is right for you? Ask our experts for advice.