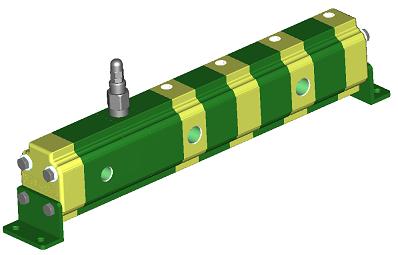

Among the possible solutions we propose for flow dividers, the less known is for sure the version FLOW DIVIDER + MOTOR.

This option is suggested when you have SINGLE ACTING CYLINDERS where there is no load on returning. Under these conditions, the starting pressure necessary to move the gears cannot be supplied by the cylinders themselves and therefore there is a risk of not returning them.

The presence of a motor connected directly to the elements of the divider, allows to provide the necessary help to cancel the opposite resistance in starting from the divider (mechanical friction), allowing the return of the cylinders.

For the sizing of the motor, the choice depends on the speed with which the returning phase must be done.

To keep the same speed moving out and moving in the cylinders, it is necessary to match the motor displacement with the sum of the displacements of the flow divider sections.

In fact, during the moving out phase the oil flow supplied by the pump goes through the sections of the flow divider and the motor is by-passed (sucks and returns to the tank), while in the moving in phase, the oil flow feeds the motor too. So if sum of displacements of the section is equal to displacement of the motor, the moving in speed is the same of the moving out one.

We have also provided hybrid solutions (for example, Gr 1 divider + Gr 2 otor), to give the best solution even for bigger displacements.

It should be noted that this solution requires a higher starting pressure, because it must also start the motor).

This increased starting pressure must be appropriately taken in consideration during the project of the equipment.

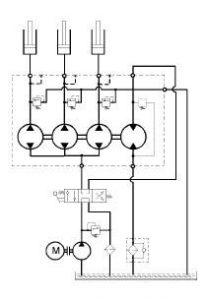

As an example, here following an application scheme of 3 sections flow divider, with re-phasing valves, and motor.