To ensure that a multivalve flow divider operates at peak performance and avoid installation errors, the first thing to do is to calibrate the phase correction valve. This step is very important because, if the adjustment is not done correctly, numerous problems can arise, including component failure.

In fact, the phase correction valves intervene at the end of the stroke to reset the error and therefore need to be properly adjusted to open at the right time.

In this article we look together at what steps to follow to properly adjust a flow divider with multiple valves.

How to adjust the phase correction valves of a multivalve flow divider

Unlike single-valve flow dividers, in which calibration is faster because it allows all elements to be adjusted simultaneously, in the case of multi-valve dividers, separate calibration of each element is required.

Starting with the first of the elements, the steps to be performed are as follows:

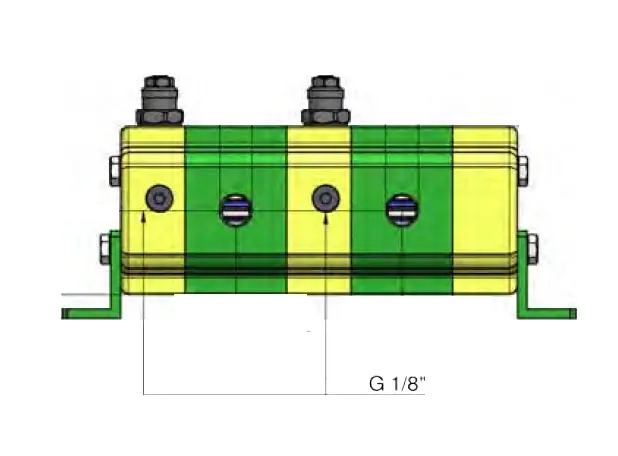

- Remove the cylindrical plug with washer covering the 1/8″ BSP port located at the valve

- Mount a pressure gauge on the port.

- Put a plug in the outlet of the element you are adjusting, leaving the outlets of all other elements unloaded.

- Get the pump running.

- Adjust the valve until the pressure gauge indicates a pressure of about 20-30 bar above the maximum use pressure and in any case below the set pressure of the system relief valve.

- Unscrew the pressure gauge and screw back the previously removed end cap.

Repeat the same operation, following the same steps, for all other valves.

Do you need help?

Contact us, we will be happy to help you out!