Is there a difference between hydraulic pumps and motors? Yes, although they are constructively similar, they have different characteristics, which concern both their specific function and other details necessary for the functioning of the product.

In this article we will see what the main differences are between the pumps and motors in the Vivoil range.

Pumps and motors have different functions

Both pumps and motors are used to make machinery used in a variety of industries, from tractors to agricultural machinery to industrial machinery. Motors with relief and/or anti-cavitation valves, for example, are useful for cooling fans because they offer dual protection against excess pressure and inertia problems.

But their operation is not identical.

In fact, the first difference between pumps and motors – and also the most important – is the function of the two components:

- pumps convert mechanical energy into hydraulic energy;

- motors, on the other hand, transform hydraulic energy into mechanical energy.

In order to perform the different functions correctly, the two products need diverse features and solutions.

Available versions

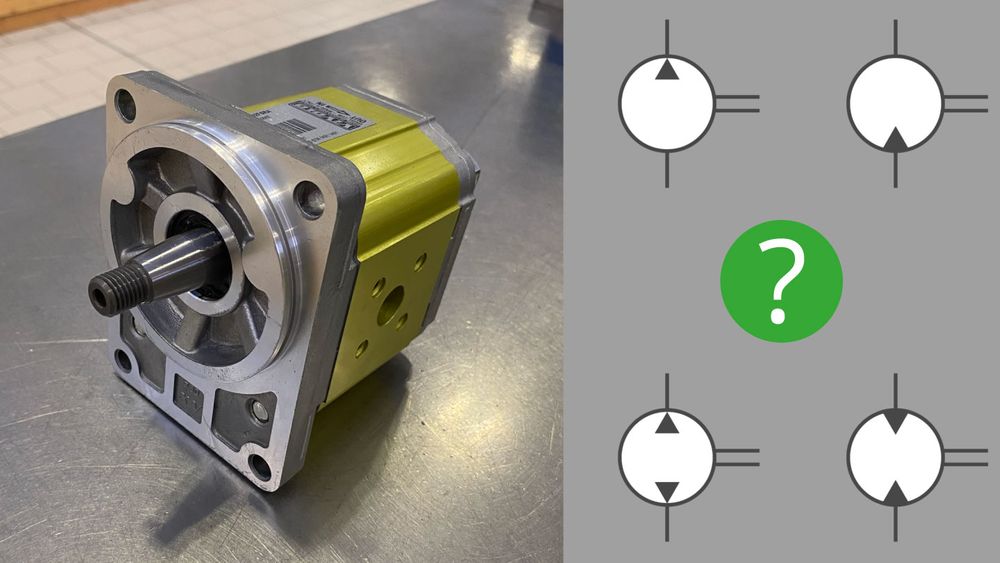

Both pumps and motors are available in two versions, unidirectional and reversible.

Unidirectional pumps and motors have only one direction of rotation: either clockwise or counterclockwise.

Reversible pumps and motors are used in applications where the direction of rotation is alternately clockwise and counterclockwise.

Pumps and motors have different tolerances

The two types of products have different machining tolerances: motor tolerances are tighter so that motors achieve the efficiency they need to work.

Reinforced oil seal

In our motors, we apply a reinforced oil seal in the front head, through the insertion of a metal support washer, which allows to bring to a higher value the resistance to back pressure.

Normally, in fact, an oil seal for pumps reaches 0.6 bar, instead, the oil seal for motors reaches 6 bar: a value 10 times higher!

This possibility is not available for all motor types, because in some cases there is not enough space to insert this type of support in the oil seal.

Testing of pumps and motors is different

Motors are tested differently from pumps. In fact, motors have, in addition to the normal test, a specific test, called “starting test”, which verifies the ability of the motor to start easily. This is because, unlike pumps, in which the shaft is driven, motors work in the opposite way: it is the oil that makes the shaft rotate.

In the case of reversible motors, which can move indifferently from one side to the other, testing is done in both directions, to make sure that the motor works properly both clockwise and counterclockwise.

Are you looking for a particular hydraulic component?

Contact us, we will be happy to help you choose the most suitable product for you.